Schwartz Machine has the capabilities of manufacturing products ranging from the fabrication of a single part to the fabrication and assembly of a complete machine or group of machines.

With 44,000 square feet of floor space, various CNC machines, and a full complement of conventional precision machining equipment, Schwartz is positioned to meet your most complex precision machining needs.

With 44,000 square feet of floor space, various CNC machines, and a full complement of conventional precision machining equipment, Schwartz is positioned to meet your most complex precision machining needs.

Schwartz can be your SINGLE SOURCE, taking responsibility for patterns, castings, and machining benefiting you with time and cost savings. We can also work with your provided material, Billet, or Casting.

We have the ability to machine one-piece conceptual projects or multi thousand-piece runs meeting your tight delivery schedule requirements with no sacrifice in part quality.

TURNING Center Capacity from 50mm (2″) to 700mm (28″) X 1500mm (60″) Travel.

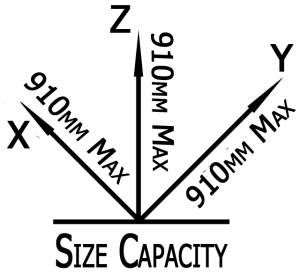

VERTICAL and HORIZONTAL Capacity: Working within a 910mm (36″) cube